|

제품명

|

QUV/uvc 시험기

|

New QUV/uvc Accelerated Weathering Tester! New QUV/uvc Accelerated Weathering Tester!

UVC 램프를 이용한 QUV/uvc 시험기

코로나를 겪고 있는 지금 우리는 제품의 살균, 멸균 등 위생처리에 대한 관심이 더 없이 높아 졌습니다. 우리가 가장 많이 사용하는 스마트폰부터, 손에 닿는 많은 제품들을 위한 전용 살균 제품이 따로 출시되고 있으며 가습기, 정수기 등의 제품엔 UV 살균 기능이 추가적으로 적용되고 있습니다.

UVC 빛은 자외선 살균(Ultraviolet Germicidal Irradiation) 부분에서 해로운 바이러스와 박테리아를 제거하는 기술로 많이 사용되고 있습니다. 특히 지표면에 도달하지 않는 254nm 의 극단파장을 이용하여 효과적으로 바이러스를 제거하고 있습니다. 이러한 극단파장은 살균에 효과적이지만 강한 UV 에너지로 인하여 플라스틱(Plastics), 가죽(Leather), 직물/섬유(Fabrics and Textiles), 코팅(Coatings) 등의 제품에 품질저하 현상을 유발 합니다.

UVC 빛에 취약한 제품 UVC 빛에 취약한 제품

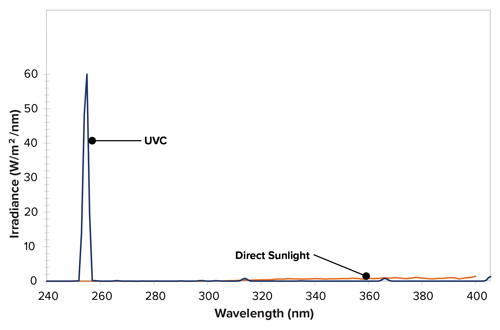

Q-Lab UVC Lamps Q-Lab 사의 QUV/uvc 장비는 UVC 램프를 이용하여 254nm 의 집중화된 자외선을 제품에 전달하여 UVC 빛에 노출된 결과에 따른 광열화 현상을 시험할 수 있습니다.  UVC 램프의 SPD UVC 램프의 SPD

Test Standard · IEC 60335-1 Annex T: 10W/m2 at 254nm, BPT 63℃, 1000 h주로 Electronic Wire Insulation 혹은 Electrical Insulating 물질에 대한 시험 규격 입니다. black panel 온도 63℃는 ISO4892-2, Xenon arc for Plastics 의 시험 규격에서 도출 되었습니다. · BIFMA HCF8.1-2019: 291 kj/m2 at 254nm, BPT 30℃, 12~24 hThe Business and Institutional Furniture Association, 미국 사무가구 생산자 협회는 UVC 에 대해 위와 같은 규격을 설정 하였습니다. 시험 온도는 특별히 규정하지 않았지만 실 사용 환경인 indoor space 를 고려할 때 30℃의 설정이 타당해 보입니다. · Typical Cycles to Simulate UVGI Exposure - Irradiance: 6 mW/cm2 at 254nm - Temperature: 30℃

시험기간은 실험을 위한 제품의 수명에 따라 달라져야 합니다. 시험 온도는 실제 사용 환경에 따라 달라져야 하지만 indoor 에서 사용되는 제품은 30도를 넘지 않는것을 추천합니다. 높은 온도는 자외선의 조도와 시너지 효과를 일으킬 수 있으며 UVC 에 의한 품질저하 현상을 관찰하는데 적합하지 않을 수 있습니다.

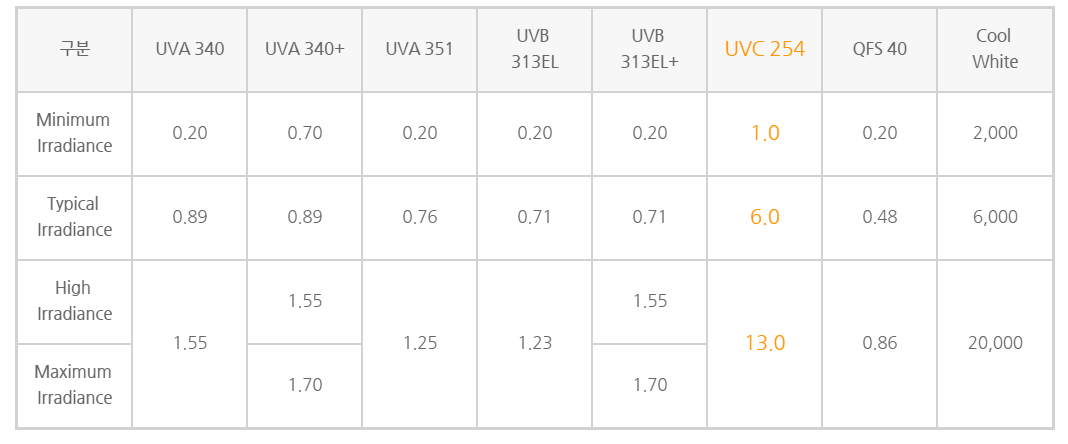

QUV Irradiance Control

단위: W/m2/nm, UVC mW/cm2, Cool White Lux

|

|

|

|

|